Helical piles are large steel shafts that are twisted into deep stable soil conditions to provide maximum structural support.

Helical Piles

The Benefits

Helical pile projects offer a number of benefits including, year-round installation, long life-span and increased load capacities. They are extremely efficient with no soil to remove and no wait time for concrete curing, which ultimately means cost savings. Helical piles offer high-quality construction while adhering to building code guidelines.

Helical Piles

Higher Load Capacity

Build Immediately

Can Be Removed

Year Round Installations

No Soil To Remove

Concrete Footings

Limited

Wait for Concrete

Increased time/labour

Permit restrictions/inspection

Permanent Install

Frost Permitting

Customer Cleanup

Helical Piles

The Process

Design

With over 10 years’ experience, the PFS team has the knowledge to help plan your next project. We work closely with expert engineers in the helical pile industry. Whether we are provided with an idea, a rough sketch, or fully detailed drawings, we can help guide and finalize your design process.

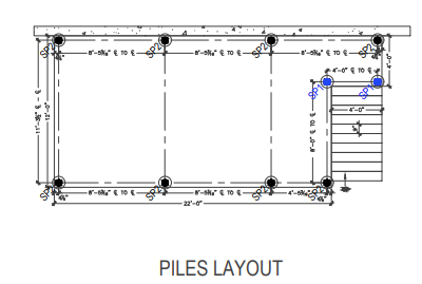

Layout

Placement of helical piles is one of the most important steps of any new foundation construction project. At Power Foundation Systems we work closely with customers and contractors throughout the entire planning phase to ensure that your helical pile project is completed effectively and efficiently.

Installation

While rotating the shaft of the helical pile, torque is applied and transferred down the shaft and to the helix plates. The helix bites into the ground acting like a corkscrew. We monitor the torque and resistance in real-time to ensure suitable soil conditions for the load capacity of each pile and ultimately the foundation for your structure.

Helical Piles

Use Cases

Use Cases

House Additions

Use Cases

Decks

Use Cases

Engineered Concrete Pads/Grade Beams

Use Cases

Hot Tubs

Use Cases

Pole Barns

Use Cases

Gazebo / Sunrooms

Use Cases

Boat House & Docks

Use Cases

Solar Panels

Use Cases

School Structures

Get In Touch

Let the experts at Power Foundation Systems guide you in your next project and help you “start off on the right footing.”